CUSTOMIZATION WITH 3D-PRINTING

The use of Selective Laser Sintering (SLS) 3D-Printing technology has been growing over the last decade predominantly for industrial use, but its advantages are really only now being seen on a large scale in B2C markets. I’ve worked with some of the leading 3D-printing companies in the world to accelerate prototyping and develop premium product lines.

This 3D-printing process presented many challenges with geometries, color-consistency and surface finishing. Solving each issue proved invaluable for future innovation of customizable products. With the introduction of 3D-printing into my development experience, I’ve now been able to work with rapid prototyping rounds and quicker testing for product styles and fits.

ARCHETYPES 2.0

VIU / FW21

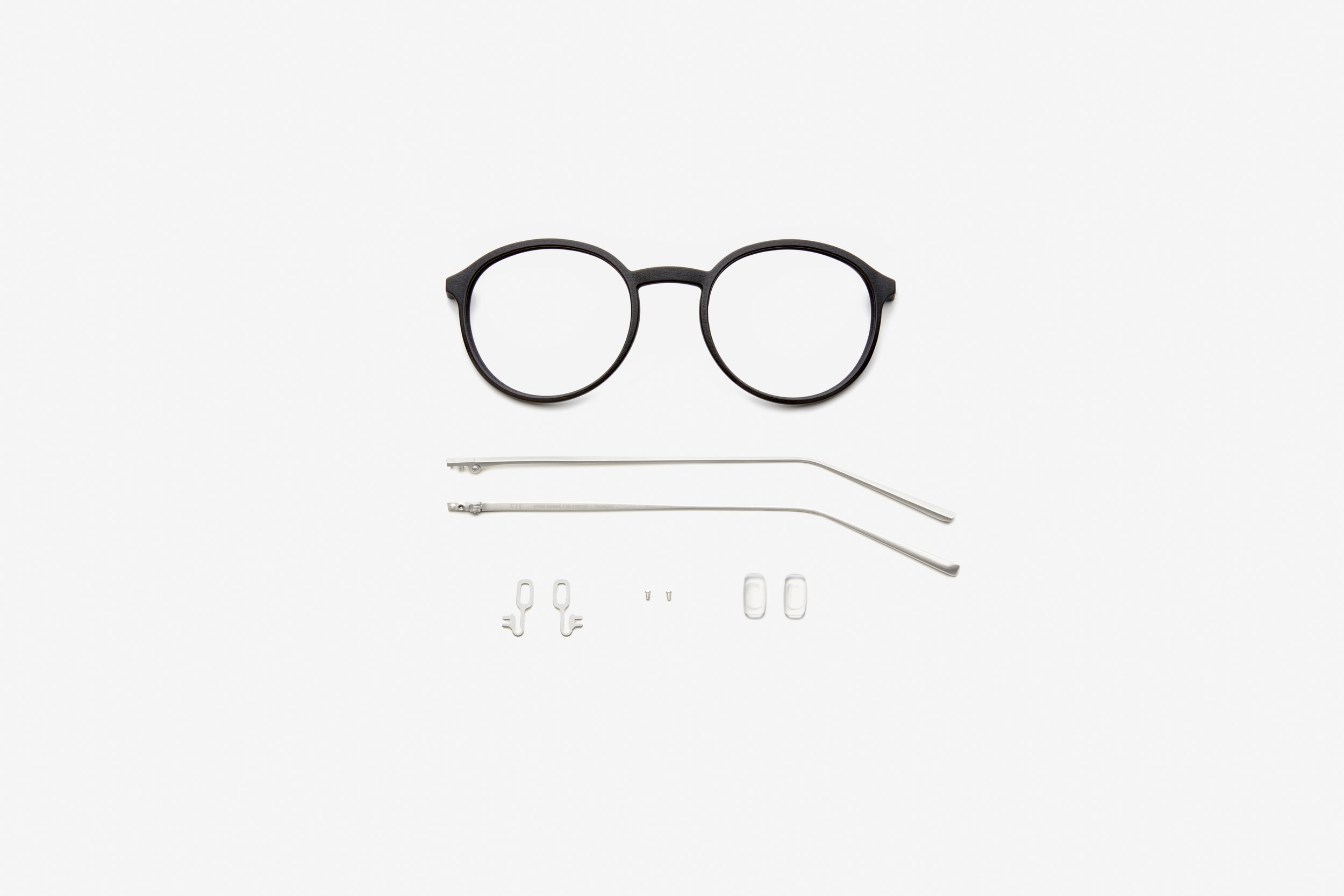

An expanded refreshment on our on-demand, bespoke eyewear. We utilized many insights from the first collection, expanded the offering to include more colors and beta-titanium combination temples to increase product visibility and offer a second, fine and delicate option for customers. An adjustable nose-arm solution was added to this collection for an even more customized fit.

This new campaign was focussed on sustainability of the collection, being made in a near zero-waste production process and creating a product just as unique as the customer.

Construction

Laser-sintered (3D-Printed) Polyamide Frame

Custom CNC milled stainless steel spring hinges

Beta-Ti Temples

CNC Stainless Steel Adjustable Nose Arms

Customization

5 Styles

8 Frame Colors

2 Hinge and Temple Colors

Custom Laser-engraved Temples to personalize each frame for the custom

In-Store Measuring Strategy for Frame Width, Nose Width, and temple length

Team

Creative Director: Fabrice Aeberhard

Designers: Kyle Sola, Andras Markus

Photography: Sandra Kennel

ARCHETYPES

VIU / SS17

On-demand, bespoke eyewear. This collection tooks years to develop and provided huge insights into the market for 3D-Printed eyewear. I worked intensely with our designers and producer using multiple analytical measures to ensure all of the designed shapes, sizes, material and colors were accurately offered and deliverable.

Launched under the campaign “Born from Dust”, this collection was focused on individual pieces built for each individual customer. This required strict alignment with Product, Marketing, Operations, and IT to ensure every customer received their bespoke piece.

Construction

Laser-sintered (3D-Printed) Polyamide Frame

Custom CNC milled stainless steel spring hinges

Customization

6 Styles

6 Frame Colors

2 Hinge Colors

Custom Laser-engraved Temples to personalize each frame for the custom

In-Store Measuring Strategy for Frame Width, Nose Width, and temple length

Team

Creative Director: Fabrice Aeberhard

Designer: Kyle Sola

Photography: Sandra Kennel